Foamtec International:

Experts in Manufacturing Technical Foam Since 1997

At Foamtec International, we take pride in our mastery of creating custom foam solutions to meet our valued customer’s unique needs. Our vertically integrated facility allows us to offer customized service to match our customer’s individual requirements. The service we provide ranges from supplying specialty polyurethane foam raw materials (sheets, rolls or buns) to just-in-time supply of finished goods.

Advanced Foam Formulations

-

Industries Served

Our comprehensive suite of services caters to a wide range of industries including automotive, consumer, industrial, medical, high-tech electronics, and beauty, enabling us to deliver customized solutions tailored to each sector's unique needs.

-

Capabilities

Foamtec’s broad spectrum of technical expertise, innovative solutions, and state-of-the-art equipment allow us to deliver exceptional quality, efficiency, and scalability to meet our clients' ever-evolving needs.

-

Applications

Our high-performance technical foam applications are ideal for a diverse array of industries, offering superior insulation, cushioning, and noise reduction properties, making them the perfect choice for automotive, aerospace, electronics, and medical device manufacturers.

-

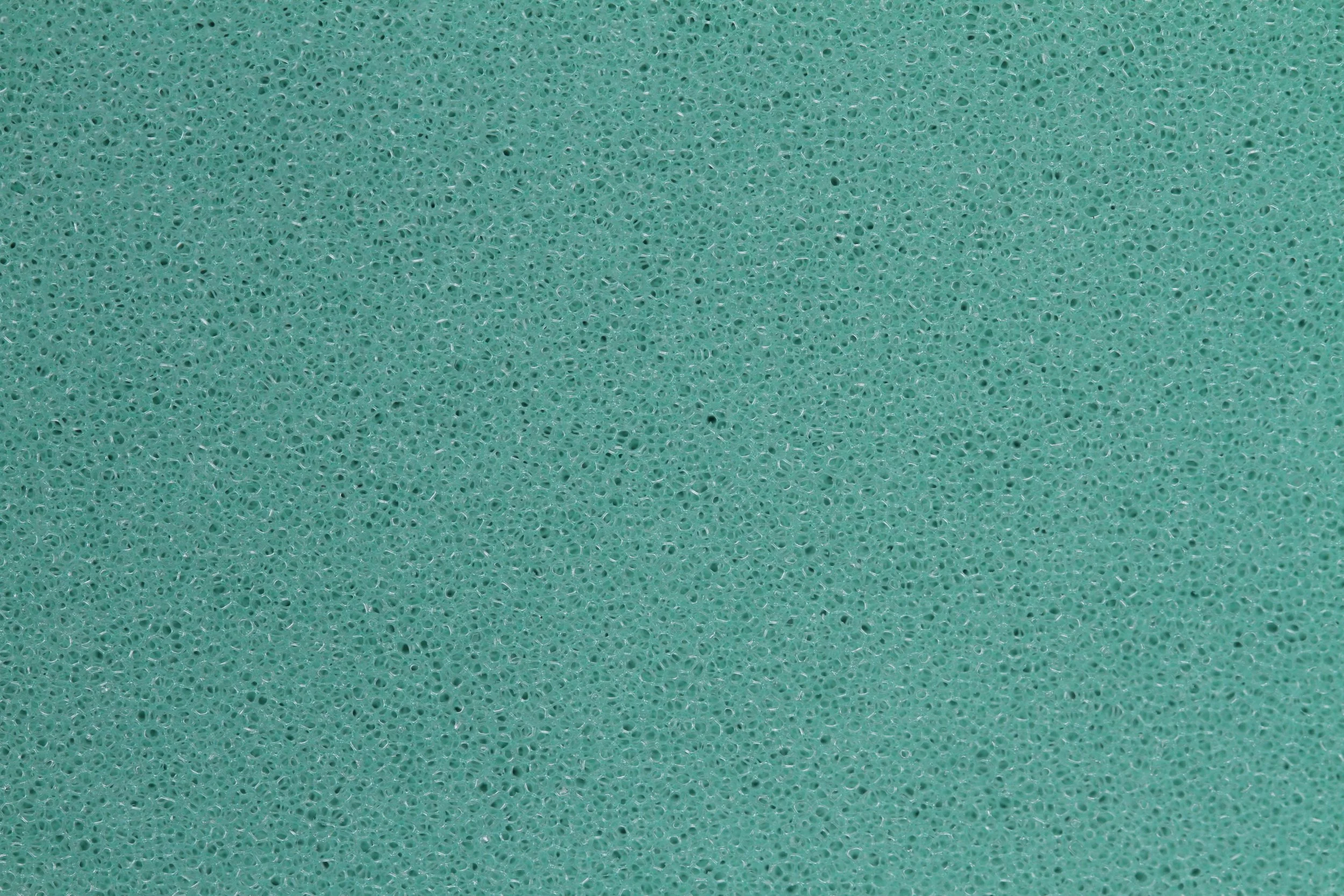

Custom Foam Formulations

We specialize in crafting custom foam solutions tailored to our valued customers' unique needs, offering personalized services through our vertically integrated facility that range from supplying specialty polyurethane foam materials to ensuring timely delivery of finished goods.

-

About Us

Foamtec International specializes in creating custom polyurethane foam solutions that integrate the best business practices from both Eastern and Western cultures. With over 25 years of experience, Foamtec is committed to continuous improvement and building long-term relationships with clients, ensuring high-quality, customized foam products that meet diverse industrial needs.

-

Blog

Your one-stop destination for the latest trends, innovations, and expert insights into the world of customized foam solutions for diverse industry applications.

The difference? Vertical Integration.

Being vertically integrated allows Foamtec International to control the entire manufacturing process.

This allows us to be an all-in-one, end-to-end solution provider.

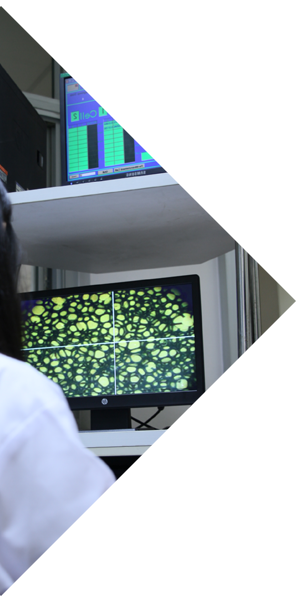

Research & Development

Foamtec's Research and Development team is robust, with over 30 specialists based in Thailand and the United States. Their focus is dedicated to resolving client challenges through collaborative efforts. This comprehensive approach supports their reputation for advancing industry standards and enhancing product performance.

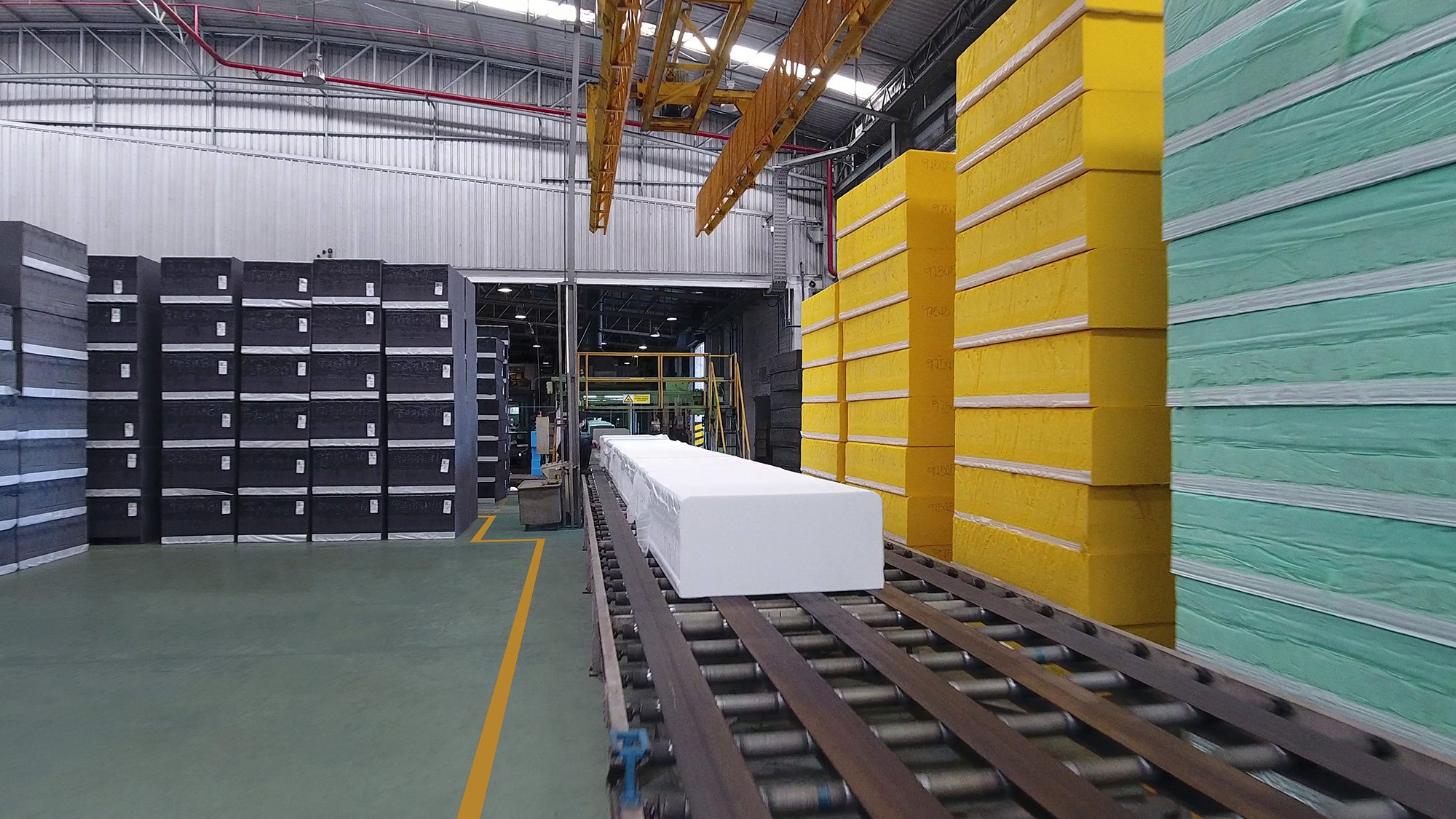

Foam

Converting

Foam

Pouring

With over 25 years of foam pouring expertise, Foamtec International is able to modify every aspect of the foam’s characteristics.

Whether it’s the color, porosity, density, cytotoxicity, absorption rate, etc…

Foamtec International is able to create the perfect foam to meet your critical criteria.

Equipped with state-of-the-art equipment, Foamtec International is able to convert foam buns/rolls into simple shapes such as sheets or complex 3D dimensions for intricate designs.

Foam

Fabrication

Our main specialty foam facility utilizes a variety of different fabrication processes to give our partners exactly what they are looking for. This includes: felting, reticulation, convolution, die cutting, slitting, lamination, hot forming, horizontal slicing, vertical cutting, & many more!

Quality

Checks

Foamtec ensures high quality in their products through rigorous quality checks. We utilize ISO and IATF certified quality management systems, reflecting their commitment to meet stringent industry standards. Our quality control processes are designed to maintain superior product standards and reliability, ensuring that all specialty polyurethane foam products meet both the technical requirements and the high expectations of their clients across various industries.

Final

Packaging

Foamtec's final packaging capabilities are integral to their quality assurance, ensuring that products are delivered in optimal condition. We use advanced packaging techniques to protect the integrity and quality of their specialty polyurethane foams during shipment. This includes tailor-made solutions that meet specific customer requirements and environmental considerations, helping to prevent damage and reduce waste.

Quality Management Systems

Foamtec’s cutting-edge foam manufacturing & converting facility is proudly accredited with ISO and IATF certifications.

Our commitment to quality management systems ensures the highest standards of excellence in every product we deliver.

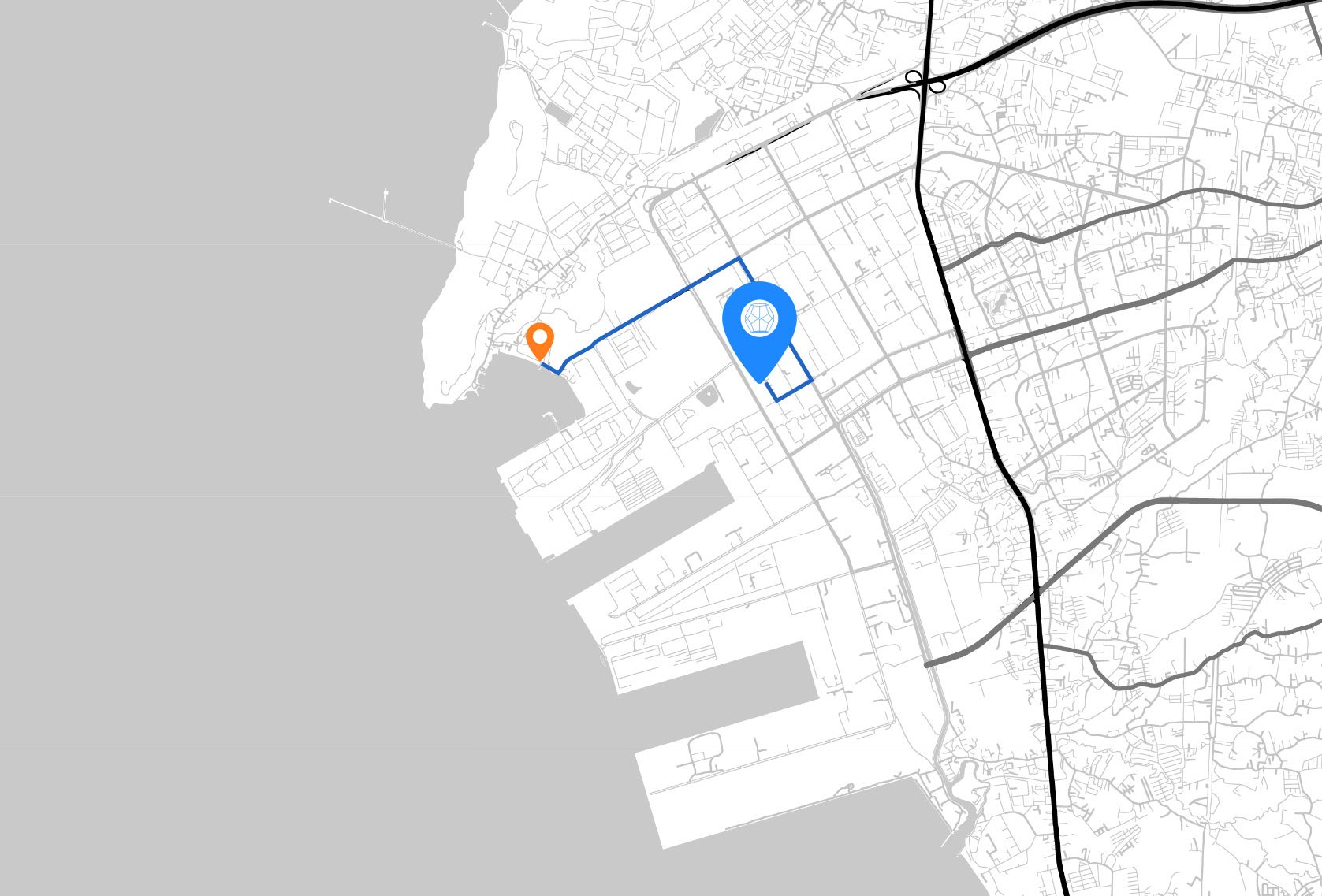

Strategically

Located.

We produce our high-quality polyurethane foam in Laem Chabang, Thailand. As one of the top foam manufacturers worldwide, our strategic location near a major port significantly enhances our operational efficiencies and customer service capabilities. This proximity allows for quicker and more economical shipping options, streamlining our supply chain and reducing transit times. It enables us to swiftly meet global market demands and maintain our competitive advantage by ensuring timely delivery of our high-quality specialty polyurethane foam products to our customers worldwide.

Contact Us

Welcome to Foamtec International - your go-to partner for all your polyurethane foam needs. Feel free to reach out and let us know how we can assist you. We strive to provide top-notch products and exceptional service tailored to your requirements.