About Us

East Meets West

Our business strategy focuses on delivering specialized polyurethane foam solutions through a global approach that integrates the top business strategies from both the East and the West.

Our Eastern-inspired methods emphasize continuous improvement and the importance of fostering long-term, cooperative relationships.

Our Western practices bring over two decades of expertise in the development, manufacturing, and enhancement of specialized polyurethane foam solutions, offering significant value to our customers.

The difference? Vertical Integration.

Being vertically integrated allows Foamtec International to control the entire manufacturing process.

This allows us to be an all-in-one, end-to-end solution provider.

Research & Development

Foamtec's Research and Development team is robust, with over 30 specialists based in Thailand and the United States. Their focus is dedicated to resolving client challenges through collaborative efforts. This comprehensive approach supports their reputation for advancing industry standards and enhancing product performance.

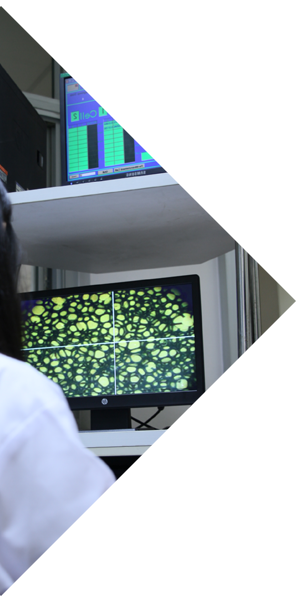

Foam

Converting

Foam

Pouring

With over 25 years of foam pouring expertise, Foamtec International is able to modify every aspect of the foam’s characteristics.

Whether it’s the color, porosity, density, cytotoxicity, absorption rate, etc…

Foamtec International is able to create the perfect foam to meet your critical criteria.

Equipped with state-of-the-art equipment, Foamtec International is able to convert foam buns/rolls into simple shapes such as sheets or complex 3D dimensions for intricate designs.

Foam

Fabrication

Our main specialty foam facility utilizes a variety of different fabrication processes to give our partners exactly what they are looking for. This includes: felting, reticulation, convolution, die cutting, slitting, lamination, hot forming, horizontal slicing, vertical cutting, & many more!

Quality

Checks

Foamtec ensures high quality in their products through rigorous quality checks. We utilize ISO and IATF certified quality management systems, reflecting their commitment to meet stringent industry standards. Our quality control processes are designed to maintain superior product standards and reliability, ensuring that all specialty polyurethane foam products meet both the technical requirements and the high expectations of their clients across various industries.

Final

Packaging

Foamtec's final packaging capabilities are integral to their quality assurance, ensuring that products are delivered in optimal condition. They utilize advanced packaging techniques to protect the integrity and quality of their specialty polyurethane foams during shipment. This includes tailor-made solutions that meet specific customer requirements and environmental considerations, helping to prevent damage and reduce waste.